If you don’t know how to choose the right sandpaper grit and type, there’s a high chance that you might end up with imperfections.

The level of success will greatly depend on the type and grit of sandpaper used. Although, most times you’ll find sandpapers that are multipurpose, what if you pick the wrong grit number? That’ll impact your sanding for sure.

For instance, plastic surfaces might require special attention compared to choosing a metal or drywall sandpaper. Cause plastic material scratches easily. Let’s go through the list of things you should consider when you’re worried about the grit and types.

Choose the Right Sandpaper Grit and Type

Although there are about 500 different kinds of sandpapers, choosing the appropriate one is quite easy. You can narrow down the important criteria you should be looking for.

Now let’s dig deeper into each one of these considerable factors.

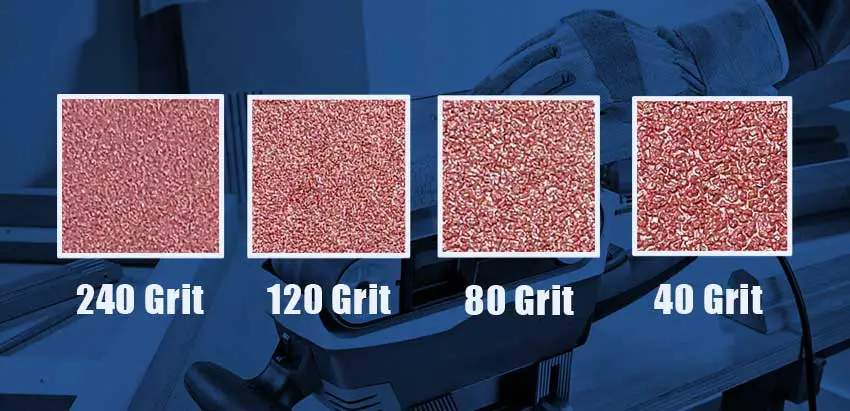

1. Different Sandpaper Grit Size

What is the difference between the different grits of sandpaper? Well, the sizes of abrasive grains determine the smoothness resulting from the surface. Additionally, it determines the rate at which the sandpaper removes materials from the surface.

Large grits/sizes remove materials faster, although they leave rougher surfaces. There are a few different systems used in indicating grit sizes. However, most people in North America prefer the CAMI system (Coated Abrasive Manufacturers Institute). Typically, the grit sizes start from 24 (coarsest) up to 1000.

Note that grits are sorted by size before they’re glued to the sandpaper.

Sandpaper Grit Chart:

- 24-36 grit indicates extra coarse sandpapers

- 40-50 grit indicates coarse sandpapers

- 60-100 grit indicates medium sandpapers

- 120-220 grit indicates fine sandpapers

- 240, 320 & 360 grit indicates very fine sandpapers

- 400-600 girt indicates super fine sandpapers

- 800-1000 grit indicates ultra-fine sandpapers

24-36 Grits

Low grit numbers represent the sandpaper’s coarseness that will enable you to remove coatings and materials. And these ranges are mostly for heavy-duty stuff like paint or, varnish removal. Thereupon, it’s aggressive on the surface and can help you at the earlier stage of the process. It comes into taking the toughest responsibilities such as, say you’re about to refinish your hardwood floor surface.

40-50 Grits

Suitable for replacing finished coat on the surface. Also, they can be applied to wood shaping projects.

60-100 Grits

After 40-50 grit has done its job. Now it’s the medium sandpaper. They’ll play a vital role in finishing the shaping process of the surface. Thus it removes any visible marks, bumps, and dent.

120-220 Grits

The chain continues to grow. Fine sandpapers would smooth the surface with its densely located abrasive materials. And this range is one among the fine grits. It can be a weapon of the final stage for most projects. Such as, 220-grit can be used as fiberglass sandpaper for finishing the painted surface.

240, 320 & 360 Grits

Ideal for finishes like polishing, removing small scratches, and buffing. It will mostly be applied to coating finishes like applying sequential paint layers. Or, even apply it to varnish coats. And the surface here gets a pretty smooth touch for welcoming another adjacent layer.

400-600 or, 800-1000 Grits

These are far more advanced versions of the very fine grit ranges. However, past experience will require choosing a superfine or, ultra-fine version.

More resources: Standard Sands for the Abrasives Industry, Abrasive grading

2. Sandpaper Types

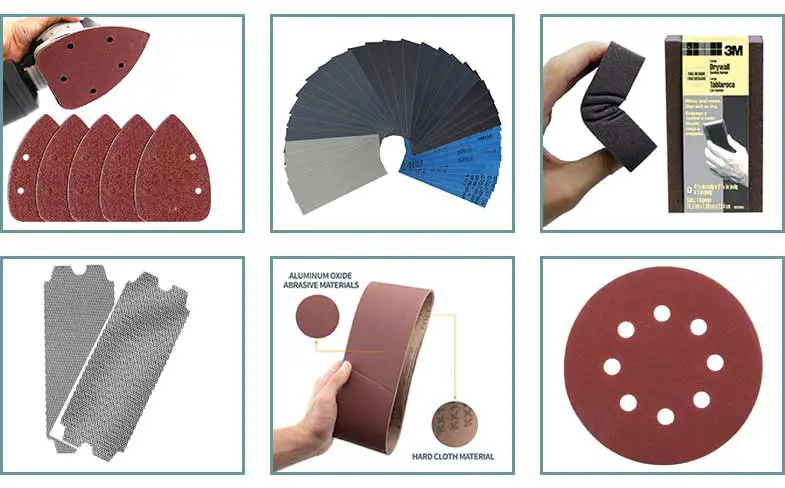

Sanding Screens

It contains fewer abrasive particles. Making it gentler than what sandpapers are. It’s designed for patching and sanding plaster/joint compounds. Moreover, screens encourage greater movement while reducing wear. The only limitation with the sanding screen is that it’s difficult to achieve a smooth finish.

Flat Sandpaper

It’s just like a flat piece of paper in a square, rectangular, circular, or mouse shape. Comes in various colors and sizes to fit the appropriate sander machine. Such as, mouse sandpaper might only be suitable with a mouse palm sander.

Sanding Belt

A circled belt used with belt sanding machines. Available in a wide variety of ranges for width and lengths.

- Width options you’ll find (in inches): ¼, ½, ¾, 1, 1.5, 2, 3, 4, 6, 25

- Length options you’ll find (in inches): 5.0, 10.68, 12, 18, 19.5, 21, 24, 30.7, 42, 48, 60, 132, 20-1/2

Sanding Sponge

It’s a reusable sanding material with a rectangular box shape. Wet sanding is much easier with sanding sponges with its abrasive side. And that helps a lot to reduce drywall sanding dust. Another side with the sponge can help you remove any residue on the surface.

3. Industrial/Commercial grade

Sandpapers can either be classified as commercial or industrial. The main difference between these two grades is the used material. Industrial-grade uses premium quality paper material, grit, and glue to bond them together. On the other hand, commercial sandpapers do not use substandard materials. However, the industrial-grade will surpass the commercial grade. Another difference between these sandpapers is the grit spacing. For this reason, they’re either classified as:

- Closed-coat, the grits are packed closely together.

- Open-coat, grits spaced further from each other.

4. Grit Material

Grit refers to the fine materials used to make sandpapers. These particles are either obtained from synthetic or natural sources. This is one of the important things that most people overlook. But it’s always a wise decision to make sure you know what you’re buying.

Flint/Emery/Garnet:

These 2 types are obtained from natural grain. Flint is suitable for coats of paint or varnish while Emery is a bit more aggressive.

Garnet:

Garnet on the other hand, with its round edges, can provide a smoother finish than Flint and Emery. It is also obtained from natural grain and comes mostly as tarnish-brown color. Lastly, this category falls under the open-coat sandpaper version.

Silicon Carbide:

These fellows are made with extremely hard synthetic abrasives. Thereupon, excellent for sanding various hard materials like plastic and metals, etc. Also, it’s commonly used in wet & dry sandpapers. It comes mainly in black color.

Aluminum Oxide:

These folk are open-coat and made with long-lasting synthetic grit. Their extremely sharp edges, making them excellent for sturdy surfaces. They last longer and wear more slowly. It comes as gray in color.

Zirconia Alumina:

It is almost similar to the Aluminum Oxide sandpaper group. Except this is not mentioned as an open coat.

5. Weight Grade

You may notice grade letters A, C, D, and E, on sandpapers. These grade letters indicate the sandpaper’s durability, with grade A being the lightest one. And, C/D is for more heavy-duty jobs compared to A grade. On the other hand, grade E being the strongest and most durable one.

6. Waterproof Capability

This group of sandpapers is made with waterproof coating i. e. able to sand in water. If you want to perform dry or wet sanding, this is the option you should explore. It will provide the results you’re looking for in a dry/wet process. Craft or, latex papers are used to make this special type of sandpaper.

The abrasives of waterproof sandpaper can be either made of Silicon Carbide or, Zirconia Alumina. But most of the time it’s based on Silicon Carbide. Based on the binder type, these sandpapers are categorized into two types:

- Low-grade waterproof sandpaper (Low-cost binder)

- High-grade waterproof sandpaper (Synthetic resin binder)

Conclusion

With that in mind, we hope that you would be able to choose the right grit and type for your sandpaper. Thanks to the researcher who brought us this in-depth guide. And make sure you share this with other seekers if you find it’s useful.

Thanks and see you soon!

Note – This compact information is in-depth internet research based. We try to help you sort out the difficulties by putting it up all together. We certainly acknowledge the validity and authenticity of the information. Subject matter experts are highly welcome for their valuable suggestions.